Products & Services

Proven Products, Proven Process

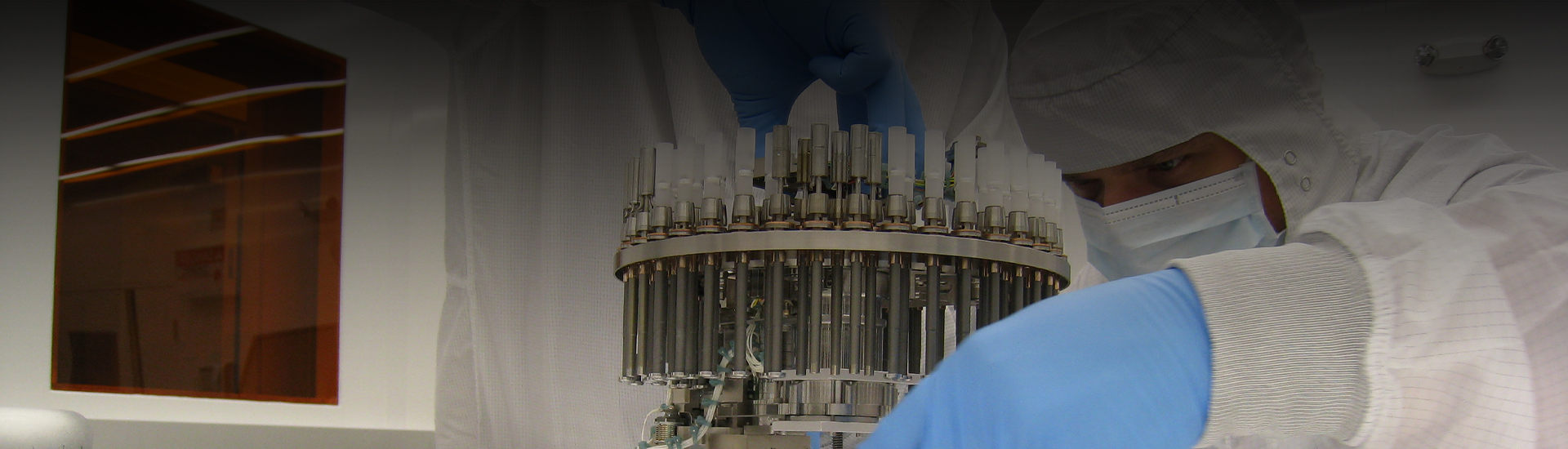

In addition to our range of products for the space community, Honeybee offers our partners a complete range of engineering, consulting, production and test services. We have the skills and experience to take projects through the full product development cycle: from early-stage feasibility studies, to designing and prototyping hardware and control systems, to production and validation.

motion control

High-performance, reliable motion control components and integrated solutions.

exploration systems

From drilling and sampling subsystems to complete solutions for planetary exploration.

infrastructure systems